Electronics Manufacturing

Ramping-up the next generation

Which is your key industrial challenge?

Get in touch with our team to discuss more about how our products and services can support you.

Designed for Strict Quality Control

Reliability

Our solutions are able to meet customers' needs across every stage of their production including Photolithography, Ion Implantation, Etching, Deposition, Plasma Cleaning, Annealing, Packaging, Testing and Assembly.

Specific Expertise

Air Liquide's Innovation Campuses in the USA, France, Germany, China, and Japan, as well as an R&D center in Korea, are all connected to world-class electronics innovation ecosystems. Each Campus is part of a global network that facilitates collaboration and the sharing of both knowledge and insights.

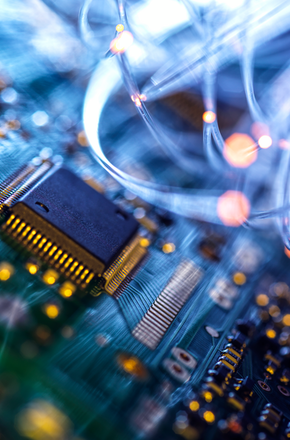

Semiconductors

This is an industry where size always matters. Semiconductors are integral to everything from processors found inside smartphones、high performance computing or computers to memory chips and image sensors, the use of semiconductor chips or integrated-circuits is now spreading outside the digital world. With every new application and end-user expectation for more performances come ever-greater challenges to produce smaller and more cost-efficient semiconductor chips.

Electronics Advanced Materials

Air Liquide's branded products for deposition and etchingComplex 3D structures are created by combining deposition with Reactive Ion Etching and Atomic Layer Etching.

Electronics Specialty Materials

High purity process gases and chemicals that can be supplied in various container sizes.Semiconductors are made of successive patterned layers of various elements, such as silicon or metals. Forming these very thin layers (just a few atoms) requires acute control over the depositing and structuring of these elements.

Industrial Gases

For inerting, cold testing, delivering precursors and other applications in electronic manufacturingManufacturing electronic devices in a sterile environment is fundamental. Our ultra-pure high purity gases guarantee the cleanliness and stability of our customers’ processes. Air Liquide supply these gases in cylinders, bulk, via pipelines or produce them at the customer’s site.

Equipment and Installations

For all necessary fluid and gas distribution, purification and on-line purity control equipmentWe supply and install gas and chemical dispense equipment for new manufacturing facilities, and support the turnkey installation of ultrapure gas and chemical distribution networks. We also provide central control and monitoring systems.

Total Gas and Chemicals Management

For our Customers' peace of mindOur specialists provide value-added services in many fields. They have a safety record, operational efficiency and reputation for creating value that has in turn made Air Liquide the industry benchmark and worldwide leader in Total Gas and Chemical Management (TGCM) services for the Electronics industry.

Photovoltaics

As the world turns to renewables, solar photovoltaic system installation has been steadily increasing. The global solar photovoltaic end-market has maintained double-digit growth in certain geographies, with various financial supports from governments.

Air Liquide supplies air gases, specialty gases, and advanced precursors used to:

- Etch silicon wafers

- Render them semiconducting, i.e., able to produce electricity via the diffusion of dopants

- Cover them with deposit thin film or apply anti-reflection coating to maximize improve efficiency light transmission

- Improve yields with innovative coatings

The challenge is to provide efficient precursors that allow manufacturers to optimize their production costs and, in so doing, make photovoltaic electricity competitive.

Flat Panel Displays

The mobility revolution is truly upon us. Thinner smart phones, cheaper tablets and lighter notebooks are just the precursor of what is in store for this new era of portable electronic devices. Yet none of these advances, or those to come, would be possible without the compact and lightweight qualities of flat panel displays.

The need to continuously improve the user experience creates demand for a new generation of displays that are cheaper, thinner, lighter, more energy-efficient, flexible and higher in resolution. Already, advances in display technology have enabled the creation of curved television sets that offer very deep contrast and smart-phones that run twice as long. Asia is the epicenter of flat panel display manufacturing, with 95% of production shared between Korea, Japan, Taiwan, China and Singapore.

Photonics

Photonics is a sensitive science that demands high-purity gases and stable gas mixtures, as well as dedicated equipment and installations to preserve gas purity.

Fibre Optics

The first step in manufacturing fiber optics is producing preform, a silica glass rod. Hydrogen, Oxygen and Helium are all used to consolidate the preform, which is then melted in a furnace and drawn into fiber optics at a rate of 1,500 to 2,000m per minute. Helium is then used to cool the drawn fiber efficiently. Air Liquide supplies these gases at ultra high purities to support fiber optics manufacturers.

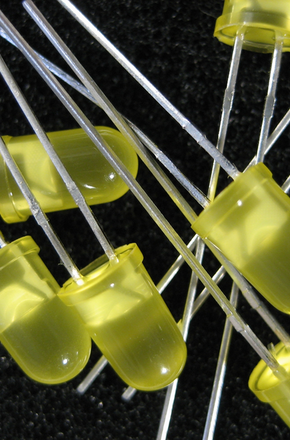

LED

Material used for white and blue LEDs needs one Nitrogen atom. This is where UHP Ammonia steps in during the deposition phase of production. In liquid form at room temperature, Ammonia must be heated to be used in gaseous phase. To allow its customers to use larger volumes of this gas, Air Liquide has developed an induction-based heating solution to vaporize UHP Ammonia more efficiently.

Our recommended gas and equipment solutions for your electronics manufacturing

We supply this key regional industry with the high-quality industrial and electronic specialty gases required to improve product quality and flexibility, reduce production cost, and resolve process-related problems. Bulk and cylinder gases are supplied for Printed Circuit Board (PCB) Assembly, Integrated Circuit (IC) Packaging and Thermal Testing operations.

Related Equipment

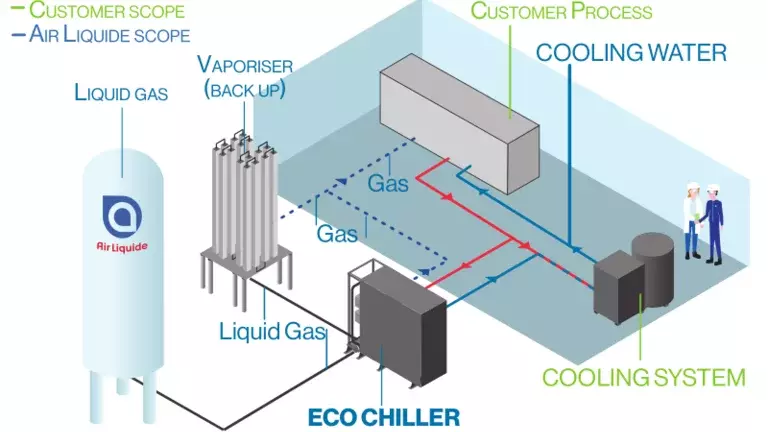

ECO CHILLER™ Heat Exchanger

Our automated heat exchanger equipment is designed to improve the efficiency of your cooling process. The system works by recycling the cold generated by the Liquid Nitrogen vaporisation, back into your cooling system and conveniently plugs into your watercooling network. The pre-cooled water thus relieves your cooling unit and reduces the energy costs of process cooling.

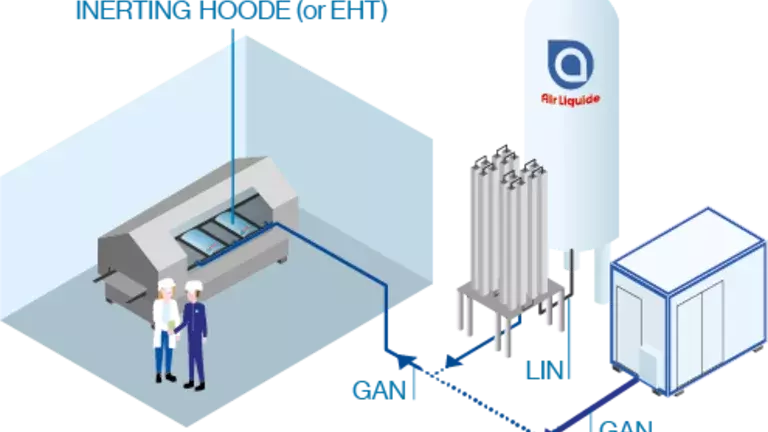

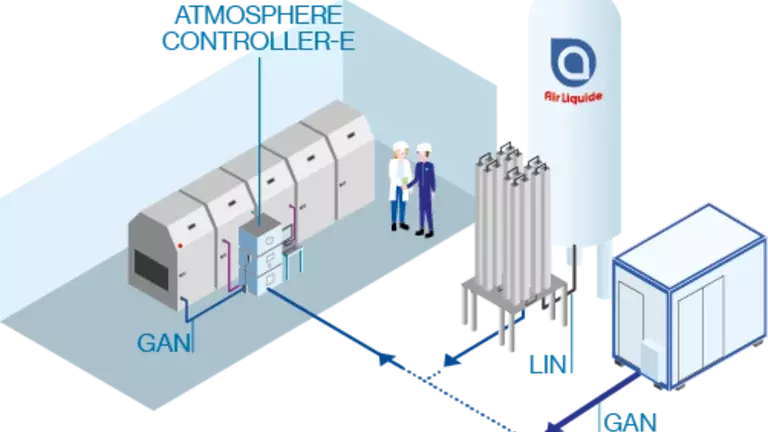

INERTWAVE™

By using heated Nitrogen for the process, INERTWAVE™ can create a more stable Nitrogen inerting atmosphere and reduce oxidation effectively, significantly improve soldering joint quality and decrease soldering defect rate. Moreover, this new generation technology enables customers to significantly reduce the flux consumption and decrease solder dross, which not only brings cost saving, but also helps protect the environment as well as improves the working conditions of operators.

INERTFLOW™

Using Nitrogen to create an inert atmosphere will protect against oxidation, poor wettability and high peak temperature. The automated control system automatically adjusts the inert atmosphere composition in the reflow oven to prevent overconsumption of Nitrogen. The installation of equipment does not require maintenance or modification of the reflow oven.

Nexelia™ for Electronics Manufacturing

While its main feature is Nitrogen supply, our all-in-one solution for the electronics manufacturing industry covers application equipment and audit services. These are an important step as they assure our solutions best reflect our customers’ unique processes. Using the audit system, we are able to: - Measure the optimal inerting atmosphere inside the reflow oven - Ensure quality and safety with verification of the atmosphere in the oven, and conduct leakage checks - Optimize performance, including the quality of soldering and Nitrogen consumption

Contact Us

Let our experts come back to you.