Glass Manufacturing

Energy efficient glassmaking operations

- Increased competition from alternative & recyclable materials (e.g. metals, plastics, etc...) for container packaging

- Regulatory pressures in terms of environmental impact

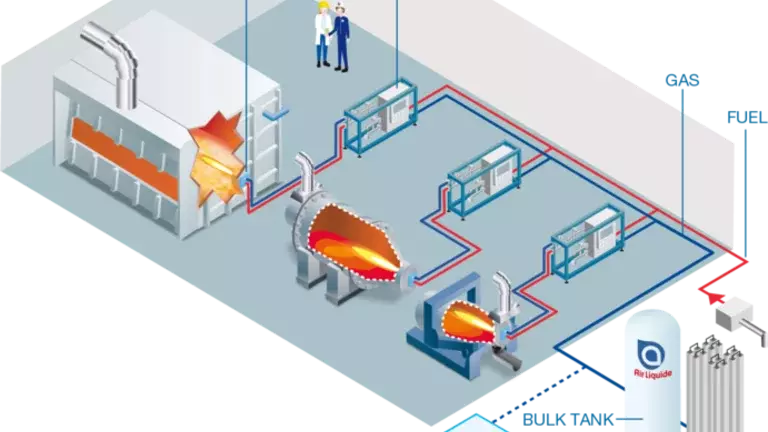

Hence, to meet these challenges, Air Liquide has developed a set of technical solutions (i.e. burners, controller & regulator, heat exchangers, simulation software) and supports for its customers from the feasibility study phases to installations and commissioning of installed solutions.

These technologies are implemented in a large number of furnaces in all segments of the glass industry (E.g. flat glass, container glass, tableware glass, technical glass & fibres glass).

What is the key challenge(s) faced by your glass production?

Get in touch with our team to discuss more about how our products and services can support you.

Inerting for Float Glass

In a float glass manufacturing, molten glass is fed onto the top of a molten tin bath in a chamber. The atmosphere inside the chamber is controlled by inerting using blends of nitrogen and hydrogen to purge and remove any oxygen that is present above the bath.

Float glass panes mostly used for windows, doors and facades.

Hence, continuous, quality & reliable supply of gas is essential to ensure uniform thickness and very flat surface on both sides of the float glass

Mold Lubrication

The ALBLACK torch has been specially developed for the lubrication of the mold walls and conveyor belts. Lubrication is achieved by depositing a thin layer of carbon deposition known as soot, produced by cracking acetylene in the high temperature oxy flame. This technology is quite commonly used in glass and crystal containers making segment.

Oxycombustion

Air Liquide partners with glass manufacturers to deliver tangible and measurable results. Oxyfuel (Oxycombustion) technology uses oxygen instead of preheated air, which has profound benefits on the installations and performance of furnaces: the energy transfer is significantly more efficient, fewer exhaust gases and longer facility shelf life. They are achieved through engineered solutions, supported by R&D teams and experts in the field. Our comprehensive offering for oxy-combustion in glass manufacturing covers Oxygen supply, proprietary burners and other value-added services.

Oxy-Fuel

Carbon footprint reductionOxy-fuel technologies offer great potential for emissions and fuel consumption reduction. At the same time, improve production capacity and flexibility. These processes are based on the replacement of Air by Oxygen. No energy is wasted to heat Nitrogen inside air, which generates unwanted NOₓ that is not used in the combustion process. Lesser CO₂ emissions can be achieved due to lower fuel consumption. Our advanced oxy-fuel combustion technologies provide optimal glass melting conditions and improve heat transfer.

Oxy-Boosting

Furnace productivityA furnace is rebuilt every 8 to 15 years. Glass manufacturers face significantly reduced productivity during plugging of their furnace regenerators. Boosting glass melting process with Oxygen is a good way to increase and maintain productivity.

There are 3 solutions:

- Enrichment of the Air with Oxygen to continue using the air burners while increasing the Oxygen concentration in the combustion Air (Typically up to 24%)

- Oxy-boosting by injecting pure Oxygen through one or more lances inserted in or near the fuel injectors

- Addition of oxy-fuel burners when a glass furnace temporarily or continuously needs to have increased heat transfer.

Reburning and Polishing of Surfaces

After forming, the marks left on the articles by forming molds must be removed. This is obtained by the local remelting of glass via oxy-gas burners to bring the necessary level of energy to the right place. For very high quality items (perfume bottles, glass tableware, high-end small and medium series bottles, container glass etc.), the entire visible surface will be very superficially remelted to produce a smooth and bright polished surface. This desired effect is achieved with Oxygen-Hydrogen burners, and is also suitable for glass surface reburning and restoration.

Insulated Glazing

For energy and cost efficient sound and thermal insulation, insulated glazing with rare gases provides an environmental friendly option to reduce conductive and convective heat loss..

Our recommended gas and equipment solutions

In Air Liquide, we provide guidance to ensure the safety of installations, implementation of anoxia detection equipment, maintenance services and training on the use of gases and our proprietary equipment.

We are ready to provide supports in every stage of your projects and our extensive offers allow you to benefit from our proprietary innovations for the glass manufacturing.

Related Equipment

ALGLASS™ Glass Melting Burner

From oxygen supply to process optimization, you'll benefit from the equipment and services associated with our oxyfuel glass melting technologies. They are suitable for all types of glass, including fiberglass, reinforcing fiberglass, lighting glass and other technical glass.

Contact Us

Let our experts come back to you.