Cement Production

Delivering gas to your point-of-use

Which is your key challenge in the cement industry?

Get in touch with our team to discuss more about how our products and services can support you.

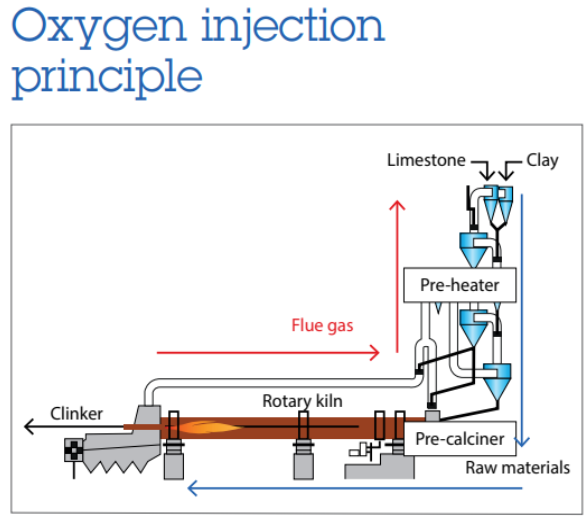

Oxy-boosting of Cement Kiln

Air is commonly used to provide the Oxygen for the combustion process to heat industrial furnaces. Oxy-boosting is based on implementing an Oxygen source to improve the process by raising flame temperatures and decreasing fumes volume. Oxy-boosting also reduces Carbon Dioxide emissions, which are harmful to both humans and the environment, while prolonging oven life.

Advantages of Oxygen

- Increase the use of alternative fuels

- Guarantee the quality of clinker

- Improve efficiency of combustion process

- Avoid ring formation in rotary kiln

- Decrease CO₂ emissions and sulphur block formation

- Decrease fossil fuel consumption

Concrete Cooling

Some construction sites require rigorous control of concrete forming temperatures. In environments where the ambient temperature is particularly high, the precise process control of concrete cooling solution with Liquid Nitrogen (LIN) makes it possible to meet the cooling requirements and to reach the temperatures necessary to pour concrete.

Our recommended gas and equipment solutions for your cement production

From basic needs to full process support, Air Liquide knows that reliable gas supply is crucial to your cement making operations.

Contact Us

Let our experts come back to you.