Aquafarming

Controlling the dissolved oxygen content to improve the productivity and sustainability aquaculture farming

In aquaculture farming, the quality of the water and the environment of the live seafoods are determining factors. Controlling the dissolved Oxygen content in the water is essential.

Hence, we recommends injecting pure oxygen into the water to have more efficient and effective aquaculture farming. A more productive alternative to conventional traditional tank aeration technologies using air.

What are your key priorities?

Get in touch with our team to discuss more about how our products and services can support you.

Oxygen Supply

- For smaller consumption amount, oxygen will be supplied in cylinders or bundles.

- For moderate consumption: Liquid oxygen, LOX can be delivered in portable cryogenics containers, micro bulk tanks

- For the oxygenation of large aquaculture ponds: Delivery of LOX by tanker in a VIE tank by Air Liquide and scheduled LOX top-up will be arranged.

- For very high and regular nominal flow rates: A dedicated oxygen production units at customer site can be proposed after in-depth study.

Reliability of Supply

- Gas level monitoring in the VIE tank using telemetry triggers scheduled oxygen supply.

- Real-time monitoring is available, T&Cs apply.

- Expert assistance on technical requirements and product safety data sheets.

Oxygen to Transport Live Seafoods

Advantages

- Allows longer distance transport

- Increase in the fish load in the tanks, optimize transportation cost per kg of fish.

- Freshness is maintained and losses avoided during the journey.

Equipment Set-up & Installation

Service

- Customised aquaculture solutions, gas supply mode and advisory of overall equipment selection, installation and commissioning.

- Evaluation of oxygen consumption

- Advise on oxynation equipment and regulation of the oxygen injected into the pools.

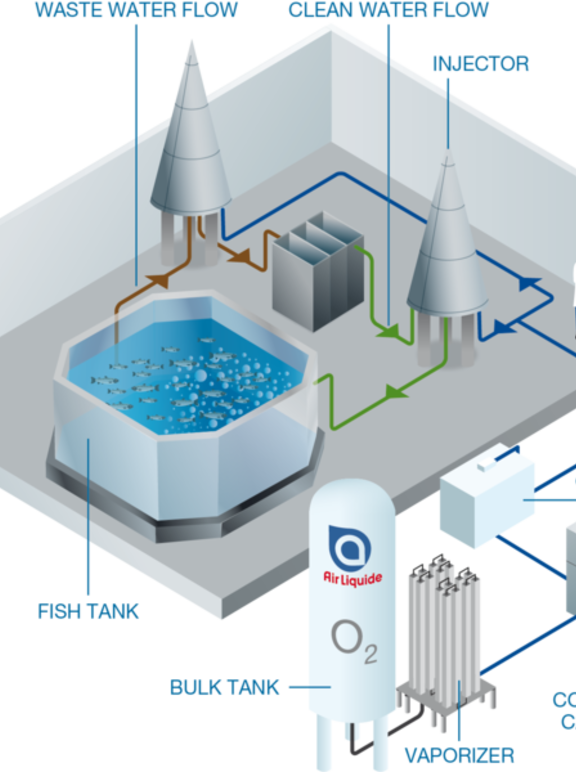

RAS and Sustainability

RAS, or Recirculated Aquaculture System, uses > 99% recycled water for high density fish cultures. Its significant contribution towards sustainability comes from excellent water usage efficiency. The system uses using the same water to culture fish continuously in higher densities and quantities, without polluting the ocean sea and/or river.

In a Recirculating Aquaculture System (RAS), our OXYFLOW ® can be installed on the main pipe. It does not require any complementary piping, nor pumps. It allows large energy savings.

-

Optimised usage of water supply & resources available

-

Protect fish from seasonal change of water conditions

-

Maintain a stable yield throughout the year

-

Achieve desire fish stocking density

Our recommended NEXELIA offer for Aquaculture solutions

Related equipment and gases:

- Oxygen

- Oxynators (Oxygen Dissolver)

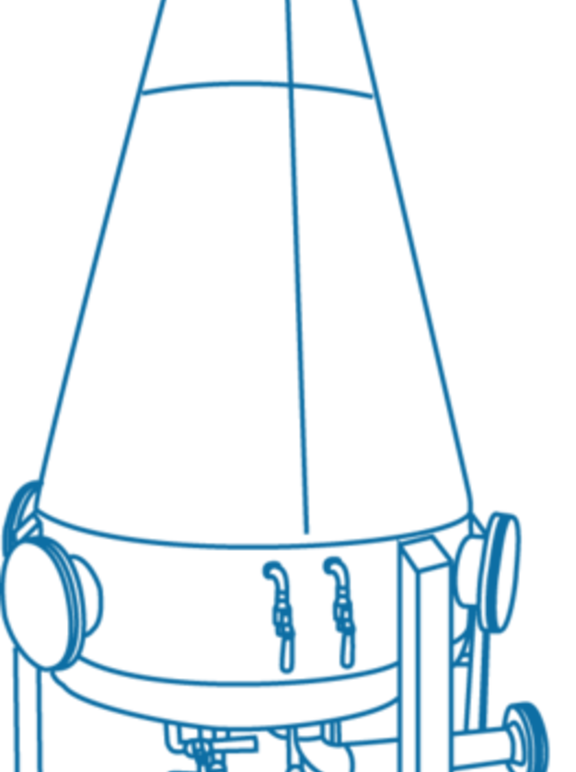

Oxycone

The Oxycone or oxygen cone is used to add oxygen to the water into the live seafoods (e.g. Fish, prawns, etc...) rearing tanks or ponds. Water enters into the Oxycone through the liquid inlet together with gaseous oxygen gas injected through the gas port. Both the liquid inlet and gas ports are located at the top of the Oxycone where the water flows down through the cone forcing the oxygen gas downward. The higher dissolved oxygen water is then channeled into the aquaculture tanks or ponds.

OXYFLOW

OXYFLOW ® is an oxygen dissolver designed for aquaculture. This device has a very high capacity of dissolution of oxygen into the water, using no, or very low, energy. Each OXYFLOW ® is manufactured according to a specific working pressure, for use in freshwater or seawater. The higher the working pressure is, the higher the outlet oxygen concentration is. The higher the water flow is, the larger the diameter and the greater the height of the OXYFLOW ® are. A complete range of OXYFLOW ® allows to answer all the needs. In a Recirculating Aquaculture System (RAS), OXYFLOW ® is installed on the main pipe. It does not require any complementary piping, nor pumps. It allows large energy savings.

OXYFOX

OXYFOX is an oxygen dissolver designed for aquaculture. This device has a very high capacity of dissolution of oxygen, using few energy. OXYFOX has been created to treat important water flows, and to cover the needs of a series of ponds, or even of the whole fish farm. OXYFOX both uses the energy of a water fall and the hydrostatic pressure in the depth of a well. The combination of these two factors unables to reach high D.O contents, with maximum oxygen efficiency.

Contact Us

Let our experts come back to you.