Beverage Applications

Solutions dedicated to beverage manufacturers

Which is your key beverage manufacturing priority?

Get in touch with our team to discuss more about how our products and services can support you.

Our beverage solution can help you:

- Preserve the colour, flavour and nutritional attributes of your beverage product with an all natural solution while optimizing your formulation costs

- Prevent the creation of an atmosphere resulting in oxidation and microbial development in your products through the production process

- Extend product shelf life and improve quality after packing by minimizing the dissolved oxygen levels which can otherwise contribute to oxidation damage

- Prevent package collapse in PET bottles and metal containers

Carbonation

The right amount of carbonation in your drink is crucial to creating the perfect bubbles in everything from water, sparking wine and soft drinks, to getting the right level of froth on a pint of beer. We carefully monitor our production of carbon dioxide and constantly work to optimize our processes. Everything to meet the requirements that apply to carbon dioxide classified for food and to meet our customers' expectations.

Carbonation

Carbonation takes place in beverage processing and bottling plants or directly at the point of consumption, such as in bars and fast food outlets.

- Meets the most stringent ISBT CO2 specifications

- Ensures CO2 product compliance to the highest food safety standards- FSSC 22000

- Includes the implementation of a Food Safety Management System within Air Liquide’s CO2 supply chain

- Provides proof of compliance documentation for inspections and internal audits

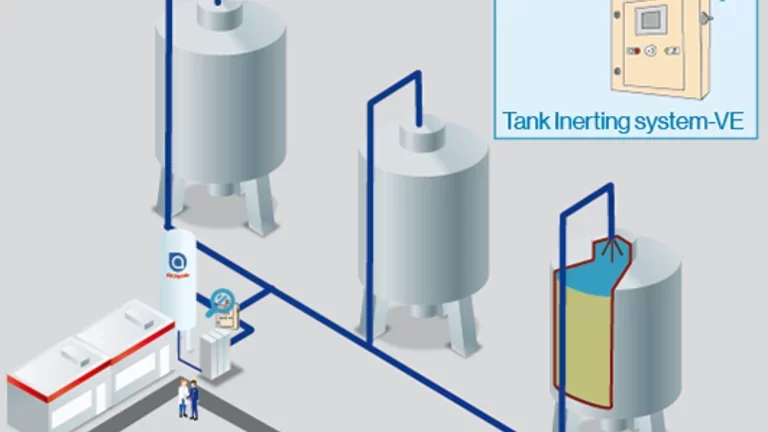

Inerting, Blanketing and Sparging

Air Liquide helps you choose a suitable method to avoid oxidation in your drink. Oxidation occurs when the empty space around a product contains moisture and oxygen, which has a negative effect on the product itself. Inerting, blanketing and sparging are the three most common ways to avoid oxidation by eliminating the Oxygen in the air around the product. When replacing Oxygen with Nitrogen or Argon, the void is filled with a dry and inert gas that protects the drink.

Dosing and Purging for Packaging

Liquid Nitrogen dosing is a unique process that helps preserve the quality of the beverage and also extends shelf life. Drops of liquid Nitrogen are injected when filling bottles and cans to expel air and reduce the Oxygen content of the liquid.

Pressurisation

Air Liquide offers environmentally friendly and cost-effective systems for pressurizing beverage packaging, especially water bottles. If you increase the pressure in the bottle, it becomes much more stable when it is filled and closed.

Air Liquide offers environmentally friendly and cost-effective systems for pressurising beverage packaging, especially water bottles. If you increase the pressure in the bottle, it becomes much more stable when it is filled and closed. A droplet of liquid nitrogen into each bottle before filling water or another beverage on top of the liquid gas. The Nitrogen vaporises and expands approximately 700 times, creating an overpressure inside the bottle.

Related Gases

Industrial Gases

Premium Gases

Related Equipment

VESTAL™ Gas Pressure Control and Monitoring Air Liquide’s VESTAL™ is a customized Nitrogen inerting and blanketing solution to help ensure product quality and safety by keeping out air. It can protect liquid products from oxidation and reduce the potential for corrosion inside tanks and vessels.

-

Industry Leader

We are a global leader in gases, technologies and services for Industry and Health. -

Reliability

Our solutions are reliable, reproducible and in compliance with stringent and ever-evolving regulations. -

Expertise

Leverage our global network of industry experts tailored to your unique challenges. -

One-Stop Solution Provider

Access a comprehensive suite of products, supply modes, and services designed for your specific requirements. -

Focus on Quality

Expect nothing less than the highest standards in process and product quality. -

Sustainability

Embrace our solutions that support your highest performance while minimising environmental impact.

Contact Us

Let our team get back to you on your specific enquiry.